Estimating the cost of rotating equipment with accuracy

The advantage of developing cost models with parametric relations is that a reliable cost estimate can be obtained just based on the process conditions/variables. Any attempt to improve the models further based on a realistically applicable set of engineering variables will enhance their accuracy. However, there is a difference in approach when tackling the rotating equipment cost models compared to the static ones.

A parametric cost model is an extremely useful tool for preparing early conceptual cost estimates when there is little technical project cost data or engineering deliverables to provide a basis for using more detailed estimating methods.

The advantage of developing cost models with parametric relations is that a reliable cost estimate can be obtained just based on the process conditions/variables. Any attempt to improve the models further based on a realistically applicable set of engineering variables will enhance their accuracy. However, there is a difference in approach when tackling the rotating equipment cost models compared to the static ones.

Rotating equipment have complex engineering design and include critical variables, severely affecting the cost. This, in turn, adds to uncertainty in estimating the cost of rotating equipment. For example, for the same input process variables in centrifugal pumps, supply cost may vary anywhere in between ‘1-32’ times the base cost, based on the factors such as pump category, driver type, seal and seal flushing plans, material class, etc.

There is a structured path with 4 steps which could be followed to tackle the uncertainty involved in estimating the cost of rotating equipment:

1. Classification of Equipment Type

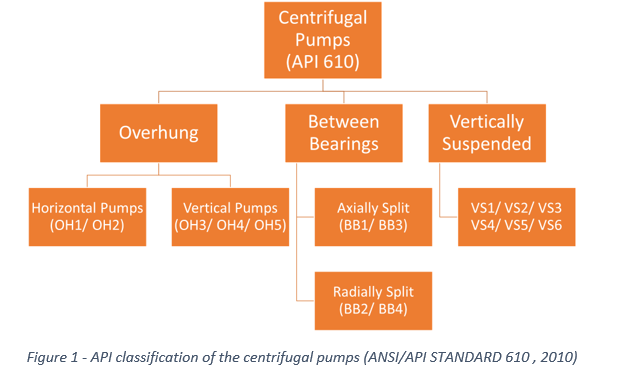

Based on the type of equipment, the design is regulated by several standardization organizations like API/ANSI. They provide the engineering guidelines for the design and construction of process equipment. Hence this is the first step involved in narrowing down the dataset available, based on the design of equipment.

2. Classification of project cost dataset

A combination of materials to be used in various parts such as impeller, casing, shaft, etc. are also classified based on the categories defined. Classifying the project cost data set will help in analyzing if relations can be derived between different classifications. Hence, the application of the standard classification, as shown below, to the large data set for a particular type of equipment will provide a sufficient basis for data analysis.

3. Selection of the drive

Classifying the dataset then leads to the question of which model to shortlist or select during the early phase of estimating. It becomes a challenge as not much is known about the detailed design. However, there are certain hints which will lead an estimator to conclude with a particular type of equipment from the list of the models.

Engineering design depends on the service for which the equipment is being used. For example, API provides a classification structure and design guidelines (API 610) for various category of pumps used in the Oil & Gas industry in different services. Narrowing down the design based on the type of service pumped would allow for the better selection of the kind of pump to be used.

Also, some of the designs available only operate at certain ranges and compels to select another type of that particular equipment beyond the specific range. Hence being insightful about the range of operating variables would further help in narrow down the kind of equipment and could lead to a more accurate determination of cost during the early estimates.

Conclusion

Engineered cost models are undoubtedly a big step in the right direction for cost calculation models. For rotating equipment, additional effort is required, and using the classification seems likely to be the key to predicting the cost of rotating equipment, especially at an early stage. Applying engineering knowledge to the traditional parametric cost models can help you a lot in improving your equipment estimate’s accuracy.

We, at the CESK Data Development Team, have been leveraging our engineering expertise to enhance our cost models. CESK data offers you a vast array of information, used by companies worldwide. The included cost data like materials, equipment, labor rates, and productivity are an industry standard and cover a wide range of disciplines for various industries.

Learn More

If you would like to talk to someone about our cost database, CESK Data, please feel free to contact us.