A conceptual estimating approach to successfully estimate capital expenditures of offshore wind parks

Utilization of wind energy is critical in reaching the EU Energy targets. The installation of offshore wind parks has been increasing steadily over the last decade. Technological developments have taken place by increasing turbine specifications, improved simulation capabilities and re-fitted ships have enabled us to install turbines in challenging offshore conditions. As a result of this, several companies would try to take advantage of this maturing technology. A substantial challenge for them is to provide an accurate early-phase estimate, considering the limited data available in the beginning.

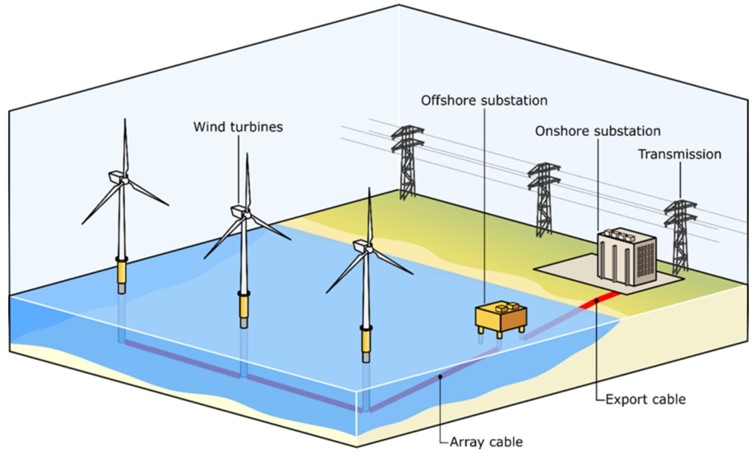

To be able to estimate the costs of an offshore wind park, we must first understand the components that make up an offshore wind park. The infrastructure that is needed to provide electricity from the offshore wind park to the end-user can be split up into three: Wind turbines, Cables and Substations (see Figure 1). The wind turbine generally consists of a rotor which is connected to a generator in the nacelle to produce the electricity. The generated electricity is then transported from the wind turbine to an offshore substation by means of array cables. At the offshore substation, the electricity is transformed and then transported to an onshore substation through the export cables.

Once the infrastructural breakdown is known, we can start with modelling the capital expenditures for each of the components by using cost data. To make such an early phase estimate, using the right cost variables is key. Key cost drivers for an offshore wind park are the installed amount of MW, the location, the foundation type, and the offshore starting year of construction.

In general, it can be said that a higher amount of installed MW leads to more capital expenditures. An average capital expenditure price per MW is estimated to be 3.09 M€/MW in 2022. Secondly, the cost ranges will differ for wind turbines and foundations depending on the geographical location of the offshore wind park. To account for this, a location factor can be applied in an early phase estimate. In addition, the foundation type of an offshore wind turbine also influences the costs. The foundation type can be fixed or floating. The most well-known example for a fixed offshore structure is the monopile. However, there is also the possibility of using a gravity-based structure or a jacket. Floating structures are not used at large scale yet, but there are possibilities such as a spar structure, tension leg platform or a semi-sub. The offshore starting year of construction is the most difficult cost driver to use in a cost estimate. This can be explained by the fact that predicting the costs of offshore wind projects starting a few years from now is difficult due to lack of data.

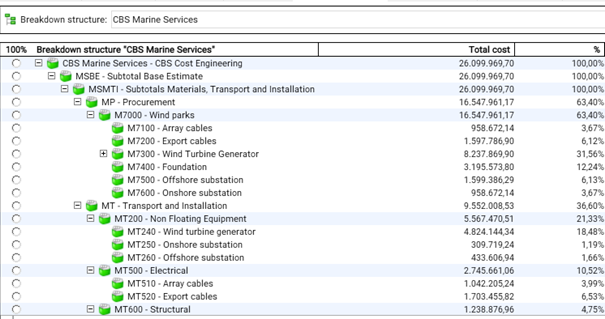

Thirdly, by combining the mentioned cost variables with the infrastructural breakdown, we can get a first high-level estimate for the capital expenditures. In general, it can be stated that the capital expenditures of an offshore wind park are largely driven by the direct costs of the wind turbines. This includes both the supply and install costs. A more detailed breakdown of the components in an offshore wind park can be produced by using a hierarchical breakdown structure. For example, the nacelle can be split up into components such as a bedplate, main bearing, main shaft, gearbox, and a generator. In this way, we can get a clear overview of the detailed cost breakdown.

Once a cost model for an offshore wind park has been produced, it is important to keep the structure of the model in a standard format. By doing this we are able to compare projects with each other and benchmark them to assess their performance. Lessons learned from past projects can be incorporated as rules/calculations within such models thereby ensuring retention of knowledge. Additionally, when integrated within the CESK (Cleopatra Enterprise Standard Knowledgebase) Data family of products, we ensure a continuous improvement of the models and standardization of the reporting procedure. The principles of “closing the loop” is implemented and its benefits are realized.

Do you want to know more about our CESK Offshore database? Please feel free to contact us.